Waste heat recovery is a topic that has been discussed a lot by large scale businesses since it can be very beneficial for the entire production process. Waste heat recovery equipment is capable of minimizing costs and reducing air pollutants, two things that are very important to large scale businesses. However, another thing that waste heat recovery systems and equipment can bring to a facility is to increase efficiency.

What is a Waste Heat Recovery System?

The main benefit of using this system is that it increases operating efficiency by recovering thermal energy released by exhaust gasses and converting it into electricity. The residual heat can then be further used for various services such as hot water or steam. A heat recovery system is made out of an exhaust gas boiler (or oil fired boiler), a turbine, and a steam turbine with an alternator.

Since the nature of these systems is to reuse already created exhaust gasses, it makes them very cost-effective in energy savings in both existing and newly implemented systems. By lowering the amount of fuel needed for production, we are lowering fuel usage, subsequently, CO2 emissions into the atmosphere. As a matter of fact, waste heat recovery systems are eco-friendly since they greatly impact how we affect the atmosphere. These systems can be implemented into your house, manufacturing facility, production plant, and even ships. All the things we just mentioned are dangerous air-pollutants.

How Will You Benefit From a Waste Heat Recovery System?

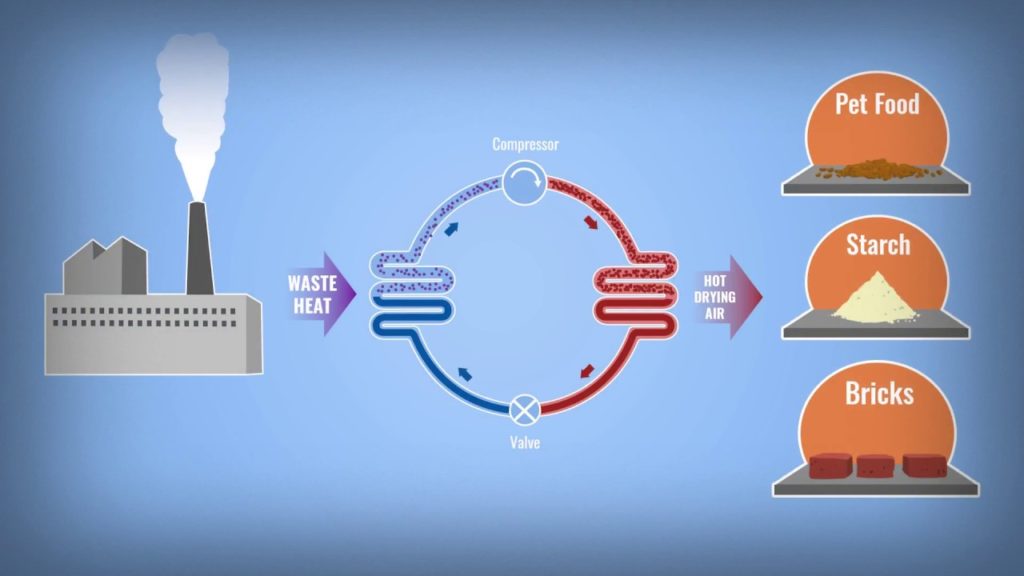

According to exodraft-varmeatervinning.se/, every large scale business that utilizes heat energy can benefit from such a system. These systems are used to a great effect in multiple industries, almost any industry that manufactures goods. Every machinery that is used in the production/manufacturing process releases exhaust gasses that are dangerous. But a waste heat recovery system can recycle those gasses and convert them into electrical energy, repeating their use for future operations. The exhaust gasses can also be used as thermal energy, for heating the industrial complex, and in combination with a liquid heating solution. Electrical energy is not the only option when it comes to recycling waste heat. Every large scale business can greatly benefit from using these systems. Some of the most notable benefits include:

Energy-Efficient Operations

Large scale businesses that have production facilities, warehouses, manufacturing plants, etc, are the ones that benefit a lot from industrial waste heat recovery systems. Waste heat recovery systems can also come much smaller for residential use. None the less, these systems are key for maintaining operating levels by being energy-efficient. Having the option to utilize the already created waste heat is something that’s slowly starting to gain traction for large scale businesses.

Turns Waste to Use

Waste heat is a problem with most large scale businesses since there was no use for it, before the introduction of these systems. Before waste heat recovery systems were a thing, the produced waste heat would be disposed into the atmosphere, subsequently increasing a production plants’ carbon footprint. Through the use of such systems, the produced waste can be utilized so it can be used to eighter heat up the entire production facility, or as “fuel” for future production.