There is no doubt that under the perfect circumstances an industrial plate heat exchangers can produce a lot of great benefits by reducing the amount of how much energy and use and by recycling a significant percentage of heat so much less goes to waste.

Whether your current facility is suitable for such a change in technology will completely depend on what you are opting for. In a new building that is completely airtight, an industrial plate heat exchanger system can present you with considerable savings.

If you are wondering about all the benefits you can get out of this type of heat exchanger and whether it is really for you, we have explained the system to help you understand if it’s worth it. This advice will apply both to non-domestic industrial plate heat exchangers.

Types of plate heat exchangers

Before getting industrial plate heat exchangers you will need to know about all the types available.

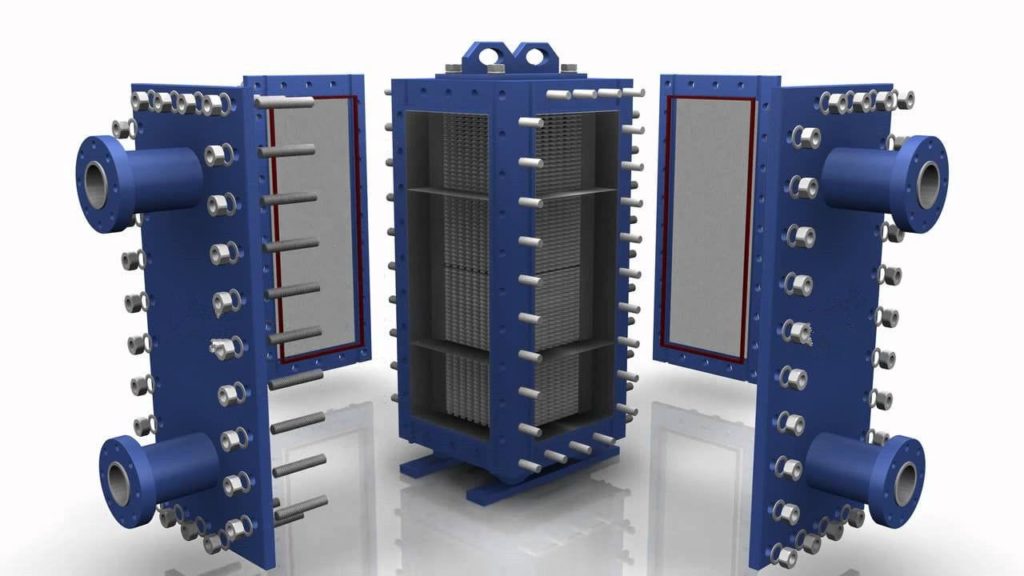

Gasketed plate heat exchangers

These heat exchangers use very high-quality gaskets and good design to seal the plates together to prevent the system to cause any leaks. Plates can be easily removed for expansion, replacing or cleaning which will drastically reduce all your maintenance costs.

Brazed Plate heat exchangers

This type of heat exchanger is used in a lot of refrigeration and industrial application. Due to the stainless steel plate composition with copper brazing, they are very resistant to corrosion or rust. These brazed plate heat exchangers are very efficient and compact, making them a great economical choice.

If you are interested in industrial plate heat exchangers, check out exodraft-heatrecovery.com

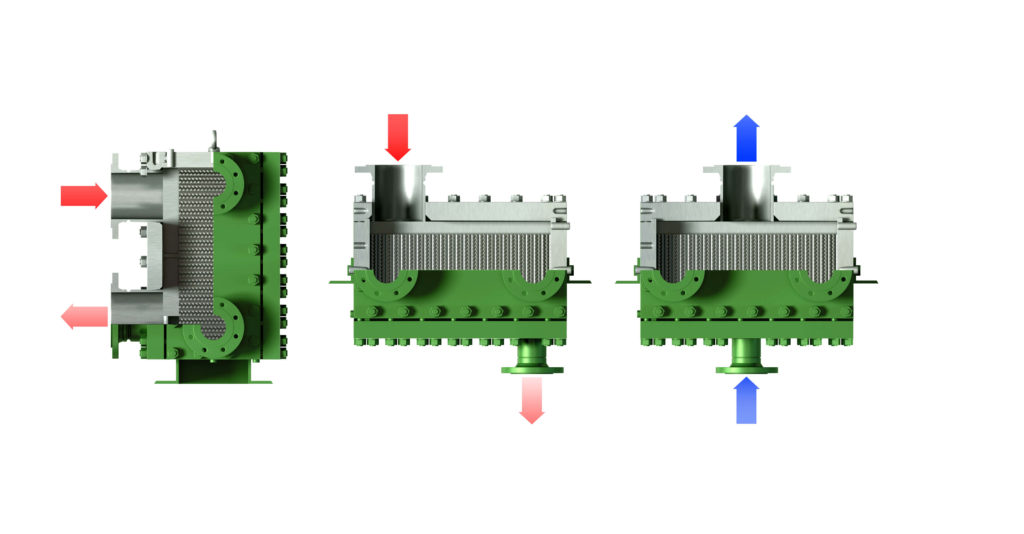

Welded plate heat exchangers

This type of plate heat exchangers is pretty similar to the gasketed plate exchangers, bud instead the plates are completely welded together. They are very durable and are great for transferring fluids with corrosive materials or high temperatures. Since these plates are welded together, any mechanical changing needed for cleaning or replacement is impossible.

Semi-welded plate heat exchangers

These semi-welded plates feature a mixture of both gasketed and welded plates. They contain two pairs of stainless steel plates welded together which are then gasketed to other plate pairs, therefore one fluid path is welded and the other path is gasketed. This results in a plate heat exchanger that can be easily serviced on one side and may also transfer much more intense fluids on the other. These semi-welded heat exchangers are great for transferring expensive materials since they have a low risk of fluid loss.

Each of these types is suited for different applications in various industrial fields.

Benefits of plate heat exchangers

Compact design

The combination of the general compact configuration and the combination of high value for the heat transfer coefficient of the flat plate heat exchanger lead to its ability the same thermal capacity as a tube and shell heat exchangers which is at least five times its size.

Easy cleaning or maintenance

The fact that these systems can be taken apart to be cleaned or replaced is a great benefit over any other type of heat exchanger systems. The plates are designed to allow for easy removal or addition to expand or reduce the heat transfer capacity.