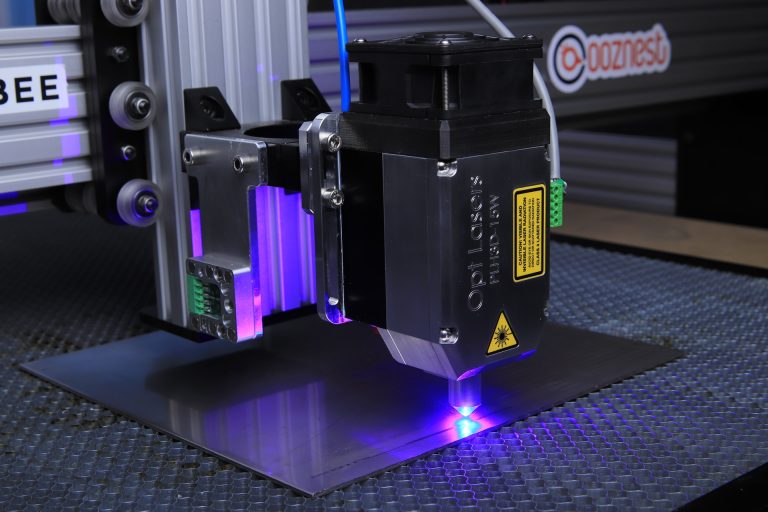

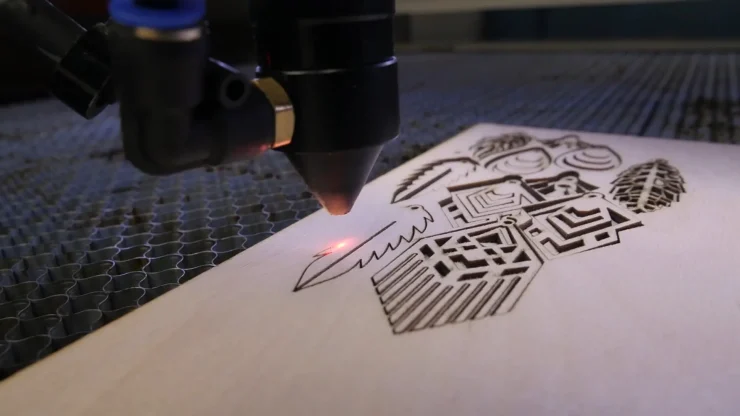

Lately, working with CNC machines has become a lucrative business. People realized that if they have an idea and creativity, they can make various items, most often from wood. With the help of these machines, it is possible to make a wall clock, various boxes, dollhouses, and many other useful and practical things, and you can also personalize each item with an engraving of your choice. Materials that can be engraved on are: wood, plexiglass, sponge, leather, rubber, glass, aluminum, stainless steel, etc.

So, the cnc laser engraving machine will definitely improve and modernize every business, but it is also important which machine you will buy, ie what you should pay special attention to.

1. Think about what you need

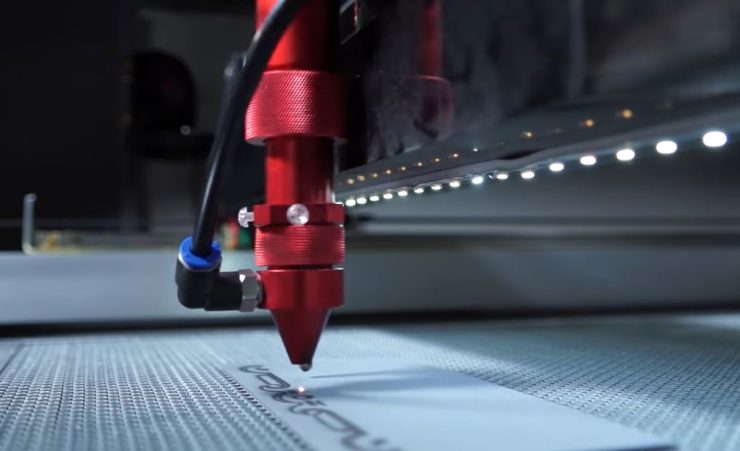

These machines differ from each other in specifications. The first thing you need to consider is whether you need a machine for mass production of certain products, for more or less processing of product parts, or simply for engraving.

If, for example, you want to start a business in the textile industry or improve it, you need a CNC machine for cutting and tailoring materials. If you are a carpenter or want to start furniture production or some other woodworking business, you need a CNC machine competitive. Management is done using preparation software that is quite simple and allows quick and easy handling.

2. Technical issues

In addition to the purpose of use, it is necessary to keep in mind the number of workers you have. If it is a machine for more sensitive and complicated jobs, keep in mind that workers will have to go through the necessary training.

Also, it is important to take into account the dimensions and weight. Keep in mind that these machines are very heavy because they are made of steel, aluminum, and polymer composite. Therefore, if you are planning to perform some more complex and demanding tasks, choose one made of steel that will ensure durability. In addition to the weight of the machine, before buying it you need to have a plan and where you will place the machine in which case the size of the same can play a big role.

3. Price

If you do not know which is better – choose the more expensive. It is recommended to always choose a machine from well-known manufacturers or one that you have heard positive reviews from those who have a little more experience working on them.

What is inevitable is that you pay attention to the accuracy of cutting and engraving, as well as the strength. The higher the power, the more power the CNC machine will consume.

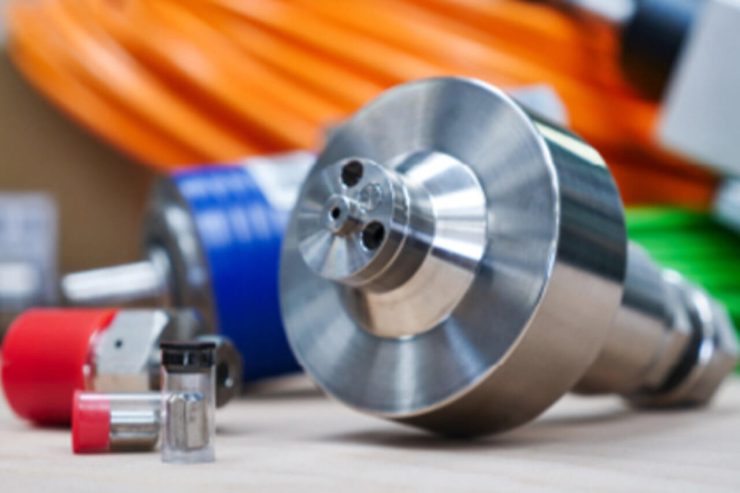

4. Spare parts

Before buying, it would not be bad to inquire about spare parts and whether there is an authorized service center in your area if a malfunction occurs. If the answer is no, continue the search.

If we have to single out some of the many advantages, they are production flexibility, 3D modeling, quality and precise workmanship with minimal deviations, availability of parts (for most manufacturers), reduction of production costs, easy handling, precise control planning, and so on. In addition to all this, many consider it an ideal opportunity to start a small business.