If you are interested in injection molding you probably know that the material used will make the biggest difference in the product. Some products need to be stern and impact-resistant, while others need to be lightweight and bendable. If you choose the wrong type of asset, your product may damage or break easily and it won’t withstand the test of time. People who are new in the business are not sure how to select the right material and what the properties are of different assets.

Even if you are not interested in producing this yourself, you should always be aware of the things you are buying. With some of these materials, you will be safe to store food, while others should only be used for products that don’t come into direct contact with us.

To help you choose the right material for injection molding and to help you understand the difference between them, we created this guide. Here you can read about the top materials used in the industry and how their properties affect the final products.

Top Materials

When it comes to doing the job right, there are some materials that are more attractive and better than others. The price of these products depends on many things, including durability, impact resistance, and strength. If you are looking for a product that is made with the injection molding process, you should consider the features the material has. Let’s look at the most commonly used assets to create these products.

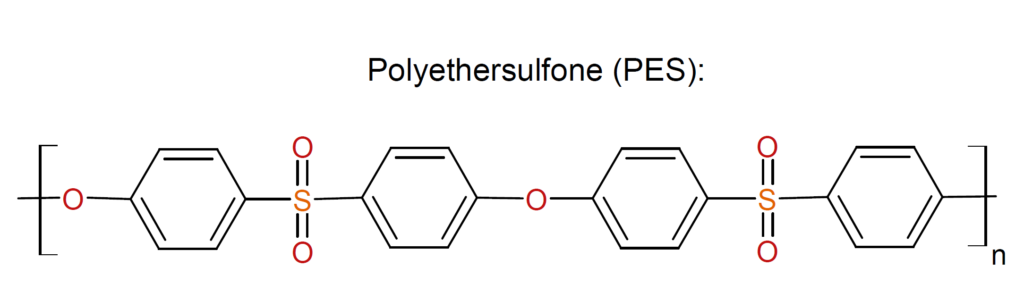

Polyethersulfone

Everything that you are using, starting from the parts of your car up to medical products, and everything in between is made from Polyethersulfone. The reason is that it can withstand even the lowest temperatures and it is relatively hard to break something made with this asset. The only issue with Polyethersulfone is that is pretty expensive to buy and because of that, the products made with it are on the costly end as well.

Acetal

Something that is used mostly to create plumbing parts and springs. It won’t get damaged by flowing water and it is relatively durable. Experts suggest that this asset won’t break easily and that is won’t shrink within time. However, if you buy something that’s made of Acetal, make sure you put it far away from harsh chemicals because they can damage or break it.

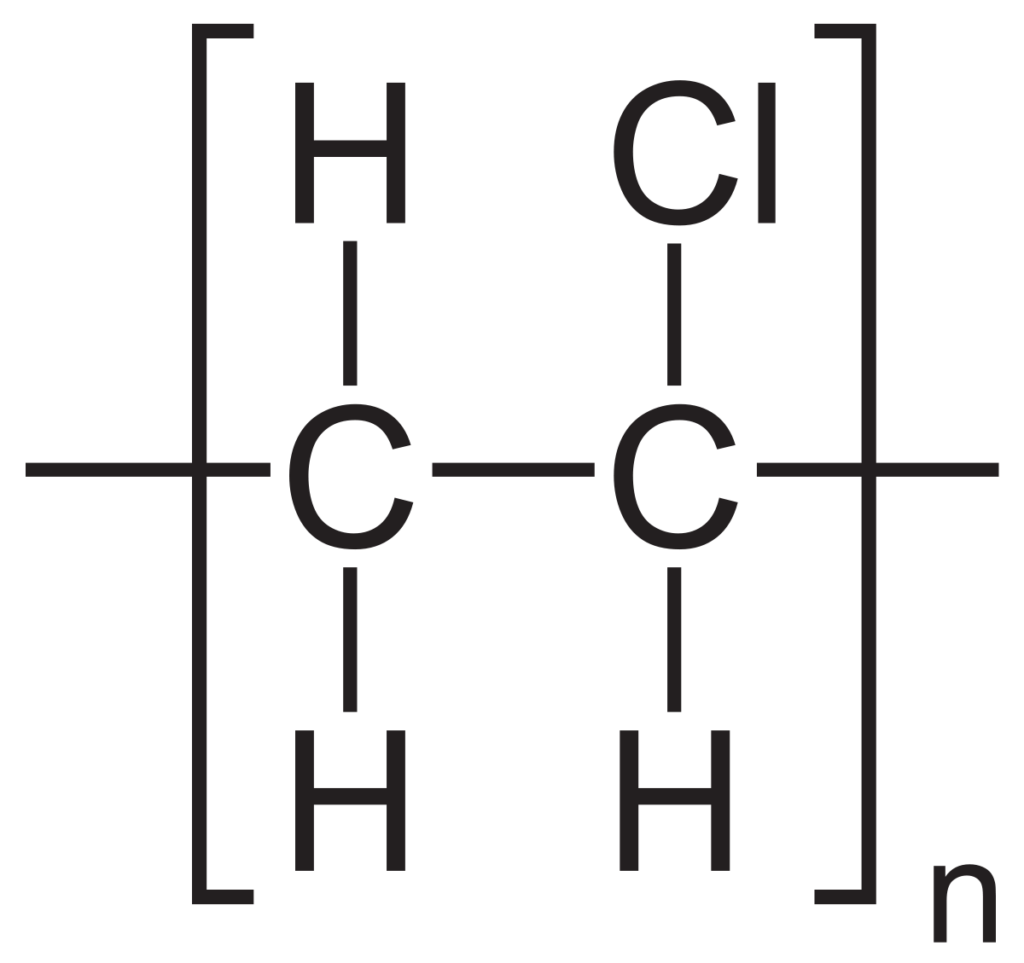

Polyvinyl Chloride (PVC)

The first thing that comes to our minds when we hear PVC are windows. It is also used to build products that can be easily bent but won’t break. These things include food containers as well as house fences.

It is a pretty affordable material and the products that are made with it are inexpensive as well. It is really resistant to extreme temperature; it does not break with use and it is also fire resistant.

Polyethylene

Something that will not get damaged easily, even when it comes in contact with harsh chemicals and acids. It is really affordable, durable, and it is lightweight. Many things that are used outdoors are made with Polyethylene because it does not get damaged by time and it is also corrosion-resistant.

If you are looking for products made with this asset, you can find it in things like children’s toys, containers, and buckets. You can safely store food in products made of Polyethylene, but you should double-check if it is safe to put it in the microwave or the freezer.

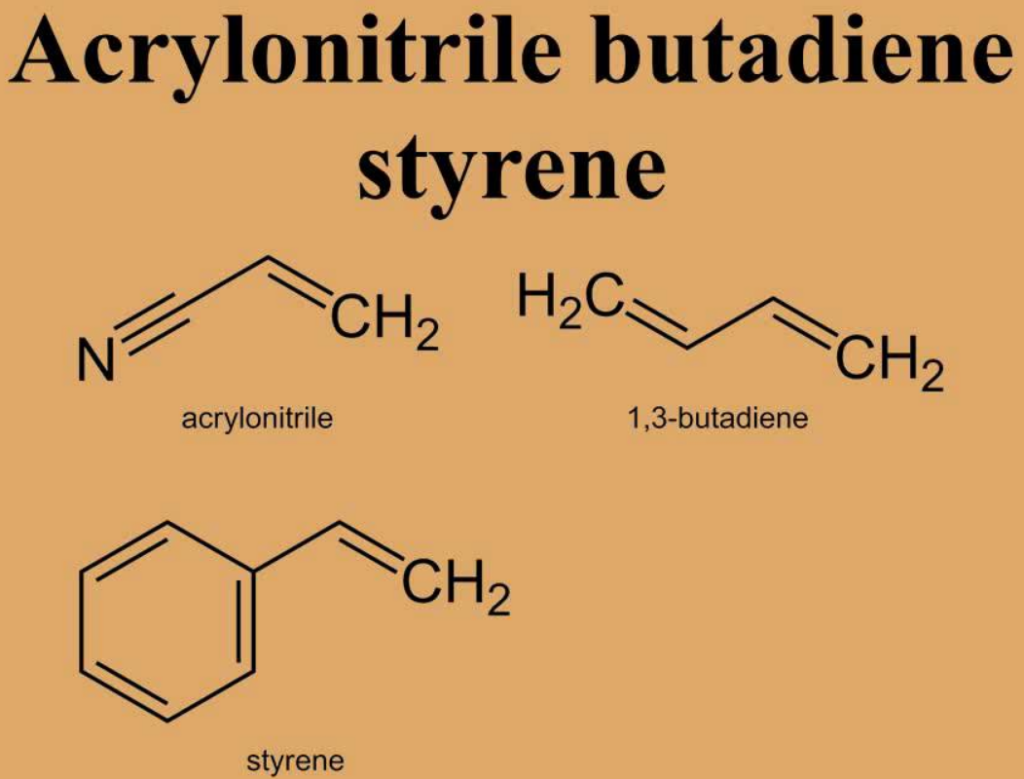

Acrylonitrile Butadiene Styrene

When it comes to the use of Acrylonitrile Butadiene Styrene in injection molding, products like toys and vehicle parts are made with it. It is pretty inexpensive, and it won’t get damaged by impact. It is acid-resistant and it is easy to work with. The only negative side to it is that it may wear in time if the products are not properly maintained.

Polypropylene

This is the number one plastic injection molding material. It is used mostly for food storing and to create consumer goods. Even though it has low strength, Polypropylene is extremely durable and has high impact resistance. Moldall.com suggests that the products depend on the material used, but also on the company that produces them. So, make sure you find things that are made up to the highest standards and that will stand the test of time.

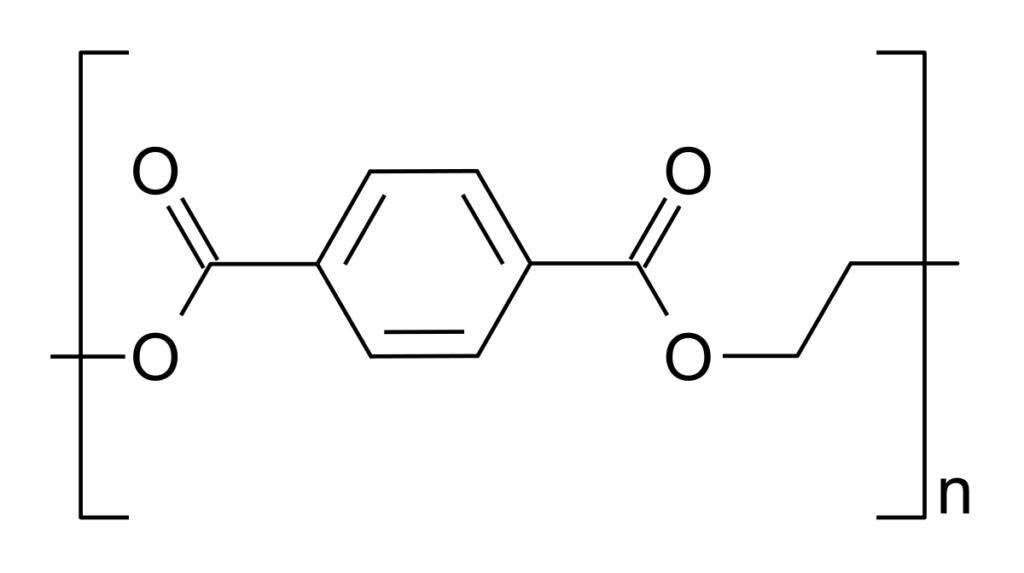

Polyethylene Terephthalate (PET)

This type of resin can be used pretty much everywhere in your household. Research says it’s great for creating anything from your kitchen appliances up to products for your kids and toddlers. The biggest reason for that is that it is really durable and it won’t get damaged by impact. It is relatively low in cost, so you can easily afford it and the products made with PET.

Thermoplastic Elastomer (TPE)

If you are looking for something that is easy to use, and it is also inexpensive, then TPE is the right choice for you. It is said that this type is great for injection molding because it can withstand temperature differences and it gives an excellent flow. It is mostly used in residential buildings, and you can find it in pretty much every home and garden store.

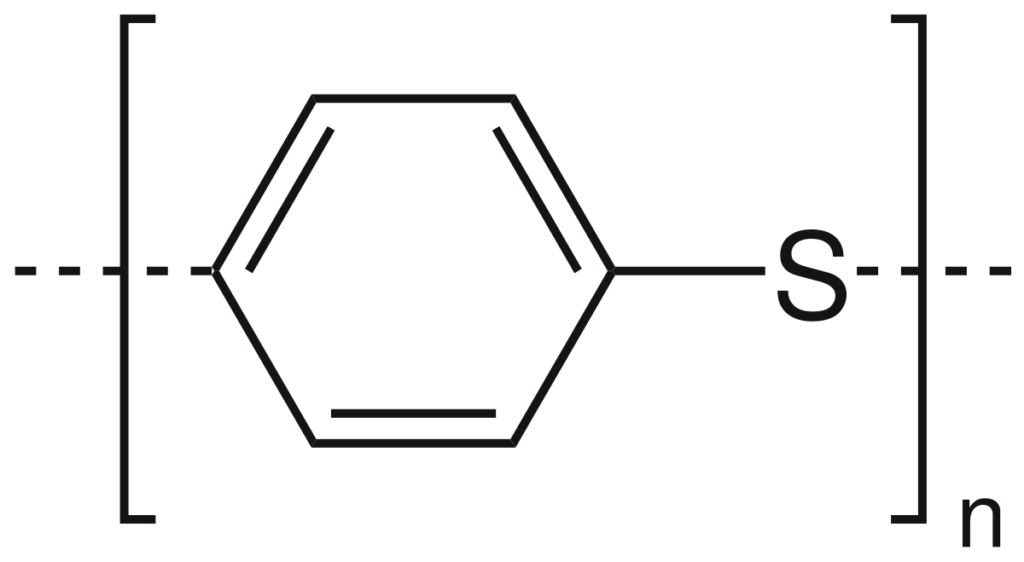

Polyphenylene Sulfide

You can find this material in almost every field and it is used to build so many different things. The great thing about it is that you don’t have to worry about it shrinking or breaking over time. Users say that it is extremely durable and the weather does not affect anything created with Polyphenylene Sulfide.

Other materials that are used in injection molding include:

- Acrylonitrile Butadiene Styrene and Polycarbonate Blend

- Polyether Imide

- Polyamide

- High-density Polyethylene

- Acrylic

- Polyvinyl Chloride

- Styrene Acrylonitrile

While reading this list you probably recognized some of the assets and if you spend some time researching the products you are using, you will realize that many of them are made with the same type of plastic or resin.

Always invest in high-quality products that are properly made and take good care of them. If you want them to withstand the test of time and if you want to use them for years to come, you need to maintain them. The seller can inform you how to clean these products and what you need to do to expend their lifetime. If you are not sure which material is best for the product you want to buy or create, then you should always consult with an expert first.